Industrial Energy Audit

Why perform an Industrial Energy Audit?

In any industry, the three top operating expenses are often found to be energy (both electrical and thermal), labor, and materials. In most assessments of the manageability of the cost or potential cost savings in each of the above components, energy would invariably emerge as a top ranker, and thus energy management function constitutes a strategic area for cost reduction. A well-done energy audit will always help managers understand more about the ways energy and fuel are used in their industry, and help to identify areas where waste can occur and where the scope for improvement exists.

The energy audit would give a positive orientation to the energy cost reduction, preventive maintenance, and quality control programs which are vital for production and utility activities. Such an audit program will help to keep the focus on variations that occur in the energy costs, availability, and reliability of supply of energy, help decide on the appropriate energy mix, identify energy conservation technologies, retrofit for energy conservation equipment, etc.

The primary objective of the energy audit is to determine ways to reduce energy consumption per unit of product output or to lower operating costs. The energy audit provides a benchmark, or reference point, for the management and assessment of energy use across the organization and provides the basis for ensuring more effective use of energy.

Types and procedures for the Industrial Energy Audit

The type of energy audit to be performed depends on:

- Function and type of industry

- Depth to which a final audit is needed, and

- Potential and magnitude of cost reduction desired

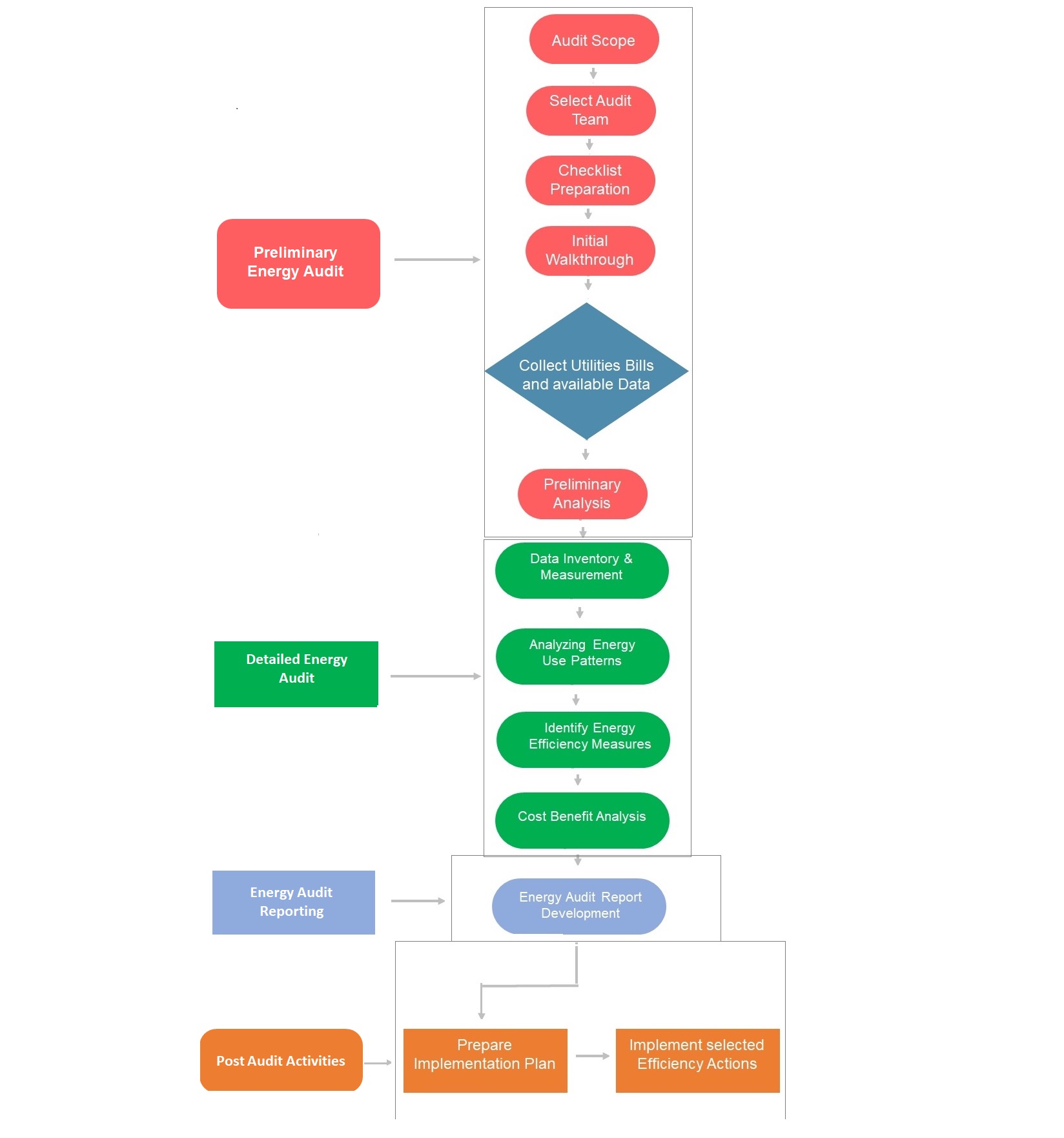

Thus energy audits can be classified into the following two types:

- Preliminary Energy Audit (PEA)

- Detailed Energy Audit (DEA)

The preliminary energy audit uses existing or easily obtained data. It is a relatively quick exercise to:

- Determine energy consumption in the organization

- Estimate the scope for saving

- Identify the most likely (and easiest areas) for attention

- Identify immediate (especially no-cost/low-cost) improvements/savings

- Set a reference point

- Identify areas for more detailed study/measurement

A PEA is essentially a data-gathering exercise that aims to develop an understanding of how energy is used in a factory and prepare a background for detailed energy audit (DEA) implementation.

A Detailed Energy Audit provides a comprehensive energy project implementation plan for a facility since it evaluates all major energy-using systems.

This type of audit offers the most accurate estimate of energy savings and cost. It considers the interactive effects of all projects, accounts for the energy use of all major equipment, and includes detailed energy cost-saving calculations and project costs.

The general flowchart of an Industrial Energy Audit can be seen here below:

#eegenergy #industrialenergyaudit #energyefficiency #industries